Underground Perimeter Control Basics

Introduction to Underground Perimeter Control

This is the first post on a series on underground perimeter control. The concepts still apply to those of you in surface mining that are interested in highwall control and crest protection.

Underground perimeter control is a general term that applies to any blasting method that is used to reduce overbreak, backbreak, and dilution. These common issues with underground mines cause downstream cost impacts to mucking, trucking, bolting and meshing, ventilation, and other parts of the mine cycle. Let’s go over some definitions before talking about blasting methods to prevent these issues.

Definitions

Backbreak is crack damage outside of the final perimeter of the blast. The cracks can be jointing or other geologic factors that are opened by the blast energy (shock or gas pressure) during detonation. They can also be fractures initiated by the blast. Backbreak can create scenarios that lead to ground fall and loose roof throughout the mine life.

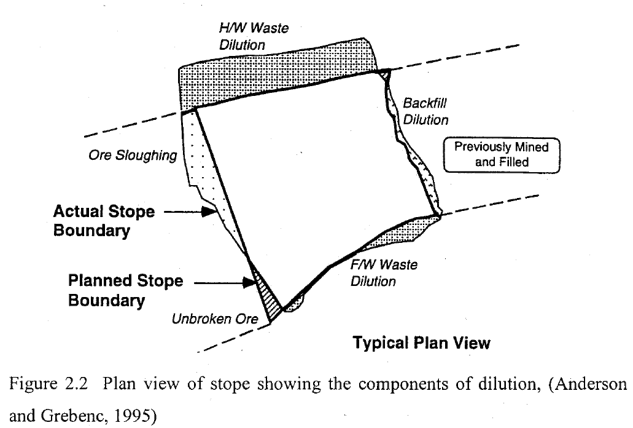

Overbreak is the material that is blasted out past the design perimeter or profile of a heading or stope. Overbreak is extra material that must be mucked and trucked out of the mine or tunnel. The overbreak material can be oversize and non-ore material (dilution), which leads to further downstream issues. Overbreak results in unnecessary downstream costs for an operation from increased ground control (bolting, meshing, shotcreting), to increased loading and hauling and processing.

Dilution is low-grade or non-ore material that reduces the value of the ore that is mucked out. Unplanned dilution can occur from overbreaking into in-situ material or backfilled material. For example, if you’re mining along a hanging wall or footwall and overbreak into the hanging wall or footwall, the non-ore host rock material that falls into the muckpile will dilute the ore beyond the dilution that was expected.

All of these common issues are typically due to three factors: geology, drilling, and blasting.

Perimeter Control Methods

This article is meant to provide a high-level overview of perimeter control methods. Follow-up articles will cover the design details for each method.

Perimeter control uses a one or a combination of smaller diameter drillholes or charges, reduced charge weight, tighter spacing and burden, decoupling, accurate delay timing, and adjusted timing and sequence to reduce the chance of backbreak, overbreak, and dilution.

Geology always plays a factor, sometimes in such a way that perimeter control might not lead to better results of an individual blast. However, when used globally over time, perimeter control design methods can decrease the overall cost of an operation significantly.

In general, there are two approaches to perimeter control: post-blast control and pre-blast control. What this means, is that perimeter control blastholes can be designed to detonate before or after the stoping or production holes in a blast. Both approaches can work well, depending on your operation.

Post-blast control methods are common in underground mining. These methods include smoothwall blasting and buffer / cushion blasting, where the perimeter holes are fired last. Usually post-blast methods are less expensive than conventional pre-blast control methods. In addition, historically, underground mining operations used long period nonelectric delays. Due to cap scatter, even on short delays, operations did not get better results by firing the perimeter holes first. Therefore, most underground perimeter control methods rely on firing the perimeter blastholes on the final delays of the blast.

Pre-blast control methods are less common in underground mining, but can produce the best results if an operation has the right design and products. These are applied on the first delays of a blast or in a separate blast before the stoping or production holes are loaded and fired. Pre-blast control methods include presplit blasting or air decking (more commonly a cost-effective surface blasting method, but proven to work underground). Line drilling, which incorporates unloaded perimeter holes, can be included in this method. Finally, another pre-blast control method that never gained much traction, is the fracture control technique. All these methods will be discussed in detail in subsequent posts.

How do the methods compare? The following figure shows the relative impact on backbreak between bulk blasting (no perimeter control), smoothwalling, and presplitting. The image also illustrates that contacts, foliation, and bedding planes work well at stopping backbreak…similar results to presplitting.

Data taken from a seismic refractive survey on backbreak at the University of Missouri-Rolla by Dr. Paul Worsey.

Follow us on social media if you’re interested in reading about the design details for each method in subsequent posts. You will learn how each method can be adapted and designed for your operation.