Underground Perimeter Control Basics: Causes of Poor Perimeter Control

Causes of Poor Perimeter Control, Leading to Overbreak, Backbreak, Dilution, and Ore Loss

Once you understand some definitions, it is import to understand some of the potential causes of poor perimeter control, which leads to overbreak, backbreak, dilution, and ore loss. The last post illustrated some definitions and a high-level overview of two perimeter control approaches: pre-blast perimeter control and post-blast perimeter control. This article discusses the main causes of poor perimeter control, along with some practical examples. Future articles will cover different methods of perimeter control and how to incorporate perimeter control in your blasts.

Note: the causes of poor perimeter control vary greatly from mine to mine or even blast to blast. This article is not meant to be a comprehensive review of every cause out there. It is a basic, high-level description of some of the main causes. If your operation has issues with poor perimeter control, this article may give you some ideas of things that you can look into, but it may not highlight the exact cause of perimeter control problems at your operation. If you have specific questions about your operation, feel free to reach out to us!

Overview

The main causes of overbreak include drilling, blasting, and geology. Excavation geometry can also be a major factor, but will not be discussed to keep the length of this article manageable. A textbook could be written on perimeter control, so rather than cover every detail of each of these causes, this post just serves as a high-level introduction with examples to each of the main causes.

Drilling includes pattern design, drilling execution and drilling accuracy.

Blasting includes loading design, product selection, explosive distribution in a blast, loading practices, and explosive performance.

Geology can really be split into multiple categories: physical properties and mechanical properties, both localized and regional. The most important characteristics are the mechanical properties. The characteristics and properties of the rock and physical structures in a rock mass will influence blast results significantly. Local and regional stresses can also be contributors to poor perimeter control results.

In general, the extent of rock breakage is a function of the diameter of the blasthole and explosive, location of neighboring holes, the explosive performance characteristics, and rock properties. All of these variables are connected, so it is important to look wholistically at the problem, rather than just one aspect of it.

Drilling

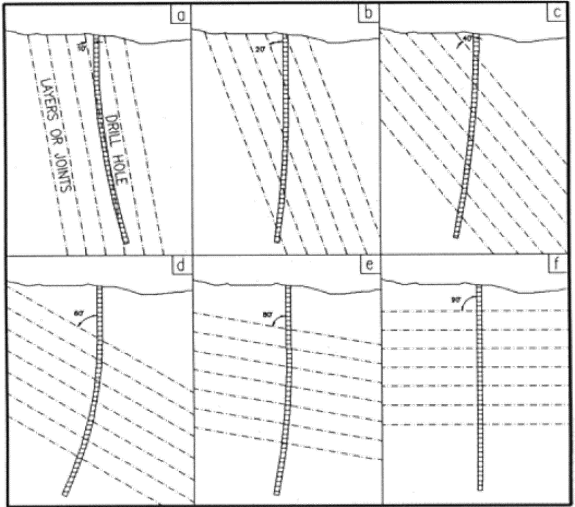

Diagram illustrating the impact of poor drilling on perimeter control (from: Singh, S.P., (1996). “The Influence of Geology on Blasthole Deviation”).

Drilling affects rock breakage as much as blasting. First, the drill pattern needs to be designed so that it takes into account the rock characteristics and explosive properties. If the selected drillhole diameter is too large, the explosive energy will create more breakage beyond the blasthole than intended. The burden and spacing are also important. The pattern dimensions and the spacing to burden ratio need to be designed so that explosive charges are not overconfined. Overconfinement leads to excessive energy being directed back into the rock outside the blast perimeter rather than fragmenting rock.

For longhole stoping, when designing the pattern, keep in mind that blastholes drilled along the perimeter of the blast can be loaded in many ways to produce better perimeter control results. Drillholes that terminate in the perimeter will produce less consistent results because the holes may be drilled too short or too long or deviate and terminate in the wrong location (see diagram).

Drilling execution is probably the biggest culprit from the drilling side and one reason that perimeter control results may lack consistency at an operation. One of the questions I’ve always considered is how much drill execution affects the final blast perimeter. If you consider a stope blast with 30 m or 100 ft holes and 5% deviation, then you’re getting around 1.5 m or 5 ft of deviation at the toe. Depending on where the toe of the hole actually ends up, the perimeter could overbreak or underbreak, leading to dilution or ore loss.

Drilling technology can help improve drill plan execution. I was part of a team that conducted a small study recently comparing as-drilled downhole surveys of manually-drilled holes vs auto-aligned holes in development blasting. In the small sample set, we found that the auto-drill alignment eliminated 50% to 60% of the drilling error.

Explosives

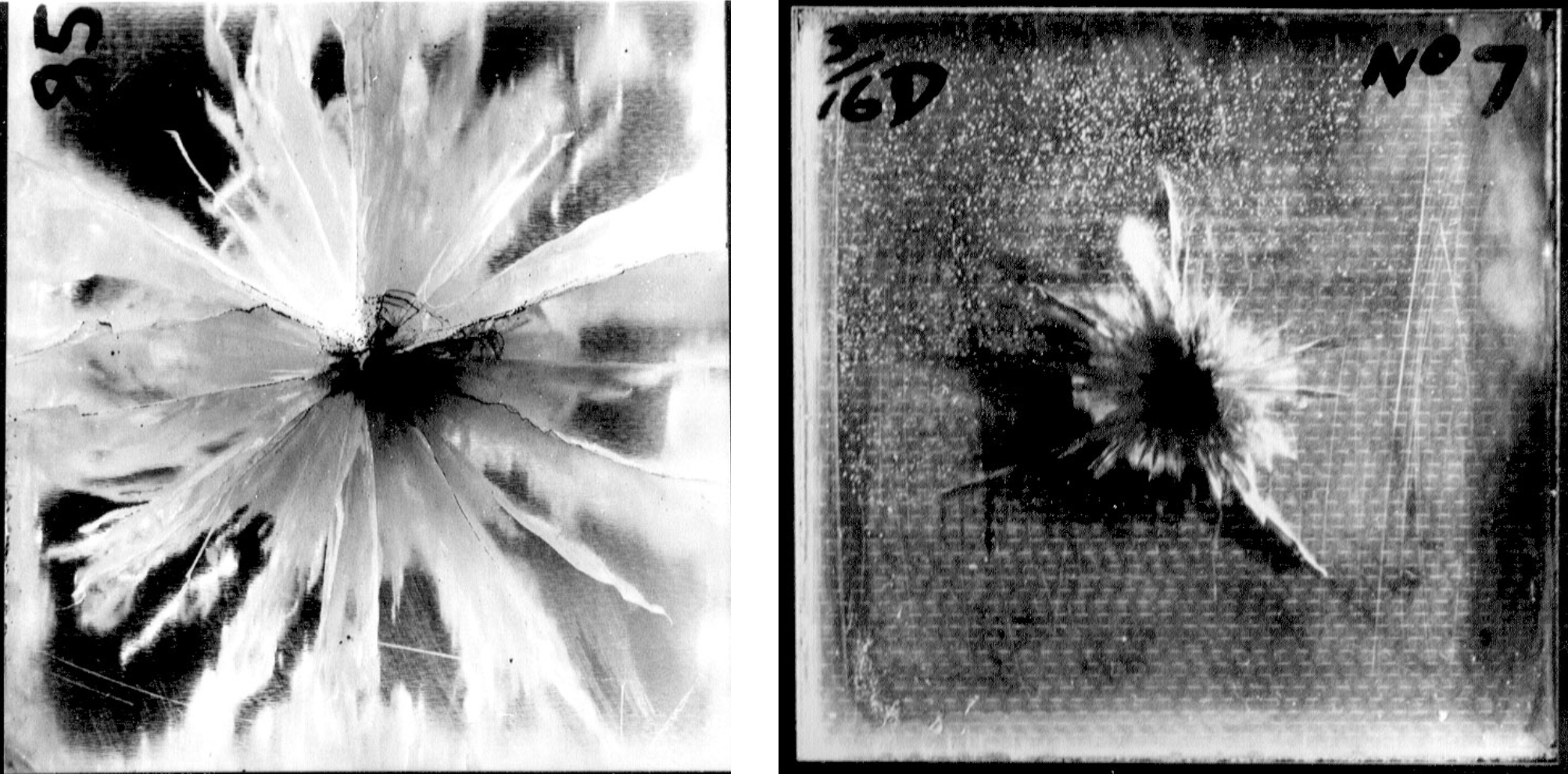

Explosive manufacturers provide certain products, both explosives and initiating systems, that have been designed and formulated to be used in perimeter control applications. Most of these products use principles such as decoupling (leaving an air gap between the explosive and the drillhole wall - see diagram), reduced energy, and timing accuracy. That does not mean you can’t get good perimeter control results without these products. However, when applied correctly, perimeter control products typically provide the best results.

Illustration of the impact that decoupling with air and water has on blast energy in rock (see image carousel below for comparison of water and air coupling in small-scale resin tests) (Source: Dr. Paul Worsey).

The loading design along the perimeter of a blast needs to ensure that the explosive energy will break to the perimeter but not past the perimeter. Design adjustments are typically required when operations move into different geologic zones. If these adjustments are not made, a blast design that works in one location may produce poor results in another location.

Inadequate application of explosives products can be a significant cause of poor perimeter control. In many cases, a design may call for the correct explosive products, but loading crews may not use them, for example, if the crews are short on time to load a blast or the product is difficult to load into the holes. In other cases, crews may be directed to light load, but due to communication errors, the crews load every hole in the perimeter to the collar.

As mentioned above, manufacturers provide products formulated for perimeter control. However, bulk products can be used if the geology suits and the explosives are loaded correctly. If loading crews are loading full column, bulk explosives on the perimeter, then the full energy of that explosive charge will likely lead to overbreak on the perimeter. If crews are light loading, gassing, decoupling, or some other method for correctly applying bulk explosives on a perimeter, then the results should be improved.

Charges can also interact causing misfires, deadpressing, or other issues. For example in a development round, if an inside charge breaks back beyond the perimeter charges, then those charges won’t detonate or break rock as planned (see image carousel below). The way mining cycles are completed now, where a heading is scaled on the shift following the blast, the driller or blaster for a round probably won’t be able to complete a post-blast inspection. Therefore, they may not realize a charge didn’t fire, so there may be no knowledge that charge-to-charge interactions are occurring at a modern mine site.

Geology

Geology may be the most important factor that affects overbreak. In my experience, it is usually the factor that is least scrutinized. It can affect drilling accuracy and explosive performance (see image carousel below). Some examples of the impact of geology were given in the discussions on drilling and blasting above. Geologic features can also impact the geometry of the opening, depending on orientation (see image at the bottom of the page). Geologic factors, such as rock stress (vertical and horizontal) and orientation, water content and pore pressure, rock strength properties (Young’s modulus, Poisson’s ratio, friction angle, UCS, Tensile strength, and dynamic strength), jointing (jointing spacing, orientation, cohesion, uniformity), and others all impact perimeter control results.

Structural geology and other geologic parameters play a major role in the performance of perimeter control methods. Structures change from blast to blast, when changing direction, or even within a blast. Perimeter control methods may not work on every blast if the structural geology is adverse; however, methods can be developed that can improve perimeter control for the majority of blasts. The best advice is that if you are going to try a perimeter control method such as those discussed in this series of posts, make sure to try it on a few blasts and compare it to your baseline blasting. Always evaluate each blast to determine if structural geology adversely affected results.

Images in this carousel: (1) Impact of joint dip on drilling (from: Singh, S.P., (1996). “The Influence of Geology on Blasthole Deviation”). (2) Impact of parallel jointing on blast overbreak results in a cut and fill drive. (3) Example of a blast where the inside charges broke back to the perimeter hole before it fired. The emulsion fell down into the muck prior to the booster firing, so the charge did not blast as designed. (4) Comparison of water-coupled charge (left) to air-coupled charge (right) in small scale resin block tests (Source: Dr. Paul Worsey).

Impact of foliation orientation to an underground opening (source: Evaluation of Long-Hole Mine Design Influences on Unplanned Ore Dilution, by J. Henning. PhD Dissertation, McGill University).

Stay tuned for more articles on underground perimeter control. The next article will focus on perimeter control products and initiation systems before we get into design recommendations and rules of thumb for different perimeter control methods.